Your current location: About us>Color Fastness Test

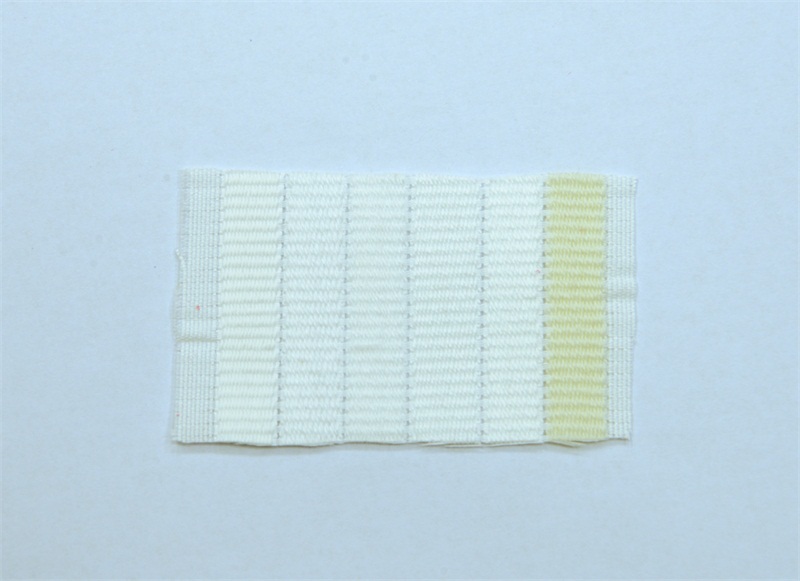

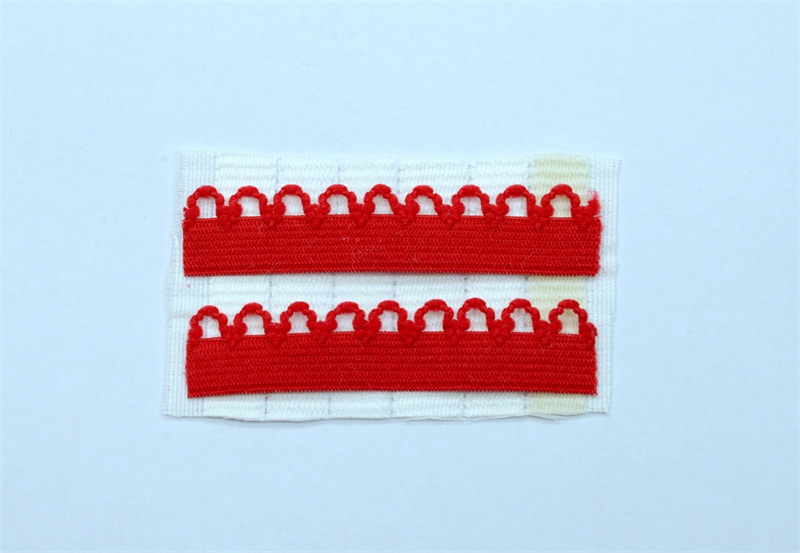

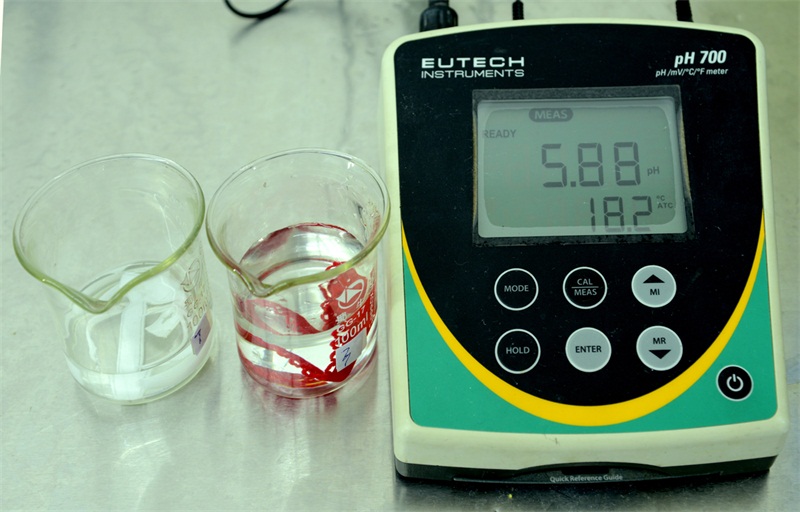

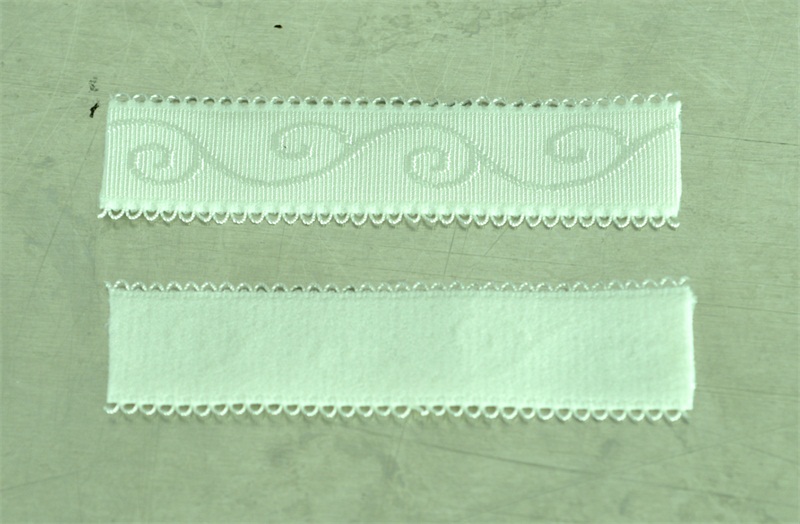

Our basic standard as follow: (ISO & GB) 1、Washing Fastness: 1.1 Standard: ISO 105 C06, change of shade grade 4 and stain grade 3-4, which tests 6 kinds of fabrics and accesses the worst one. GB/T3921, change of shade grade 4, stain on cotton 3-4, which only tests cotton. 1.2 Testing Theory: Stitch sample and the adjacent fabric together, set up all testing conditions, and put them into soap liquid. Then wash them with cold water and dry.At the end, access the change of shade of sample and the stain of fabric. 1.3 Testing Conditions: (ISO testing conditions and GB testing conditions are the same) a. Soap liquid concentration: SDC soap powder vs water=5gVS1L b. Soap liquid: sample VS soap liquid=1VS50 c.Temperature: 50℃ d. Time: 0.5hour e. Steel ball 10pcs 1.4 Our equipment: 2、Rubbing Fastness: 2.1 Standard: ISO 105-12 Dry Rubbing Fastness Grade 4, Wet Rubbing Grade 3 and dark color eet rubbing Fastness Grade 2-3. GB/T3920 Dry Rubbing Fastness Grade 3-4, Wet Rubbing Fastness Grade 3 and dark color wet rubbing Fastness Grade 2-3. 2.2 Testing Theory: Rub the sample against dry and wet cloth separately, and access the stain color fastness on cloth. 2.3 Testing Conditions:(ISO testing conditions and GB testing conditions are the same) a. Number of rubbing: 10 times b. Vertical pressure: 9N c. Reciprocation motion: 10 CM 2.4 Our equipment: 3. Water Fastness: 3.1 Standard: ISO 105 E01, change of shade grade 4 and stain grade 3-4 GB/T5713, change of shade grade 4 and stain grade 3-4 3.2 Testing Theory: Fit sample and the adjacent fabric together. After soaking in water, place them between two board for a while and dry. Then, access the change of shade of sample and the stain color of the adjacent fabric. 3.3 Testing Conditions: (ISO testing conditions and GB testing conditions are the same) a. Temperarure:37℃ b. Time: 4 hours c. Pressure: 12.5ka (equal to 5kg) 3.4 Our equipment: 4、Perspiration Fastness: 4.1 Standard: ISO 105 E04, change of shade grade 4 and stain grade 3-4 GB/T3922, change of shade grade 4 and stain grade 3-4 4.2 Testing Theory: Fit sample and the adjacent fabric together. After soaking in artificial perspiration, place them between two boards for a while and dry. Then, access the change of shade of sample and the stain color of the adjacent fabric. 4.3 Testing Conditions: (ISO testing conditions and GB testing conditions are the same) a. Temperature:37℃ b. Time: 4 hours c. Pressure: 12.5ka (equal to 5kg) 4.4 Our equipment: 5、Light color fastness: 5.1 Standard: ISO-105 B02-2014 fastness level 3-4 GB8427-2008 fastness level 4-5 5.2 Testing Theory: Cover with the jig half of test sample while the other half expose.put it inside the Q-Sun xenon test chamber aging faded test. Take it out after twelve hours,two side faded grade and compare SDC Standard of blue wool cloth ,assess the change of color. 5.3 Testing Conditions: 5.4 Our equipment: 6、PH Value: 6.1 Standard: ISO 3071 4-7.5 GB/T7573 4.0-7.5 6.2 Testing Theory: Put sample into distilled water and extract for a certain while, and measure the PH value by PH meter from the extract liquor. 6.3 Testing Conditions: a. Requirement on distilled water: ISO 5-7.5 GB 5-6.5 b. distilled water Dosage: 100ml/ sample c. sample Weight: 2g/sample d. Testing Time: ISO: 2 hours in room temperature GB: 1 hour in room temperature 6.4 Our equipment: 7、Phenolic Yellowing Color Fastness: 7.1 Standard: ISO 105-X18 2007, Grade 3-4, Stocking for 6 months GB/T29778 2013, Grade 3-4, Stocking for 6 months 7.2 Testing Theory: Put the sample on a piece of paper, fold the paper so that the paper can cover the sample, put them on test instrument of perspiration fastness with the cloth, place them in the oven for keeping warm. After a certain period, withdraw them, assess the change of color. 7.3 Testing Conditions: a. Temperature: 50℃ b. Time: 18 hours c. Pressure: 12.5ka (equal to 5kg) 7.4 our equipment: Comparison between ISO standards and GB standards

Besides above-mentioned testing items, we can test other testing items according to client’s requirement and offer the reports. Remark: Due to the limits of dyes, the fastness of fluorescence series can only meet the GB standard. |