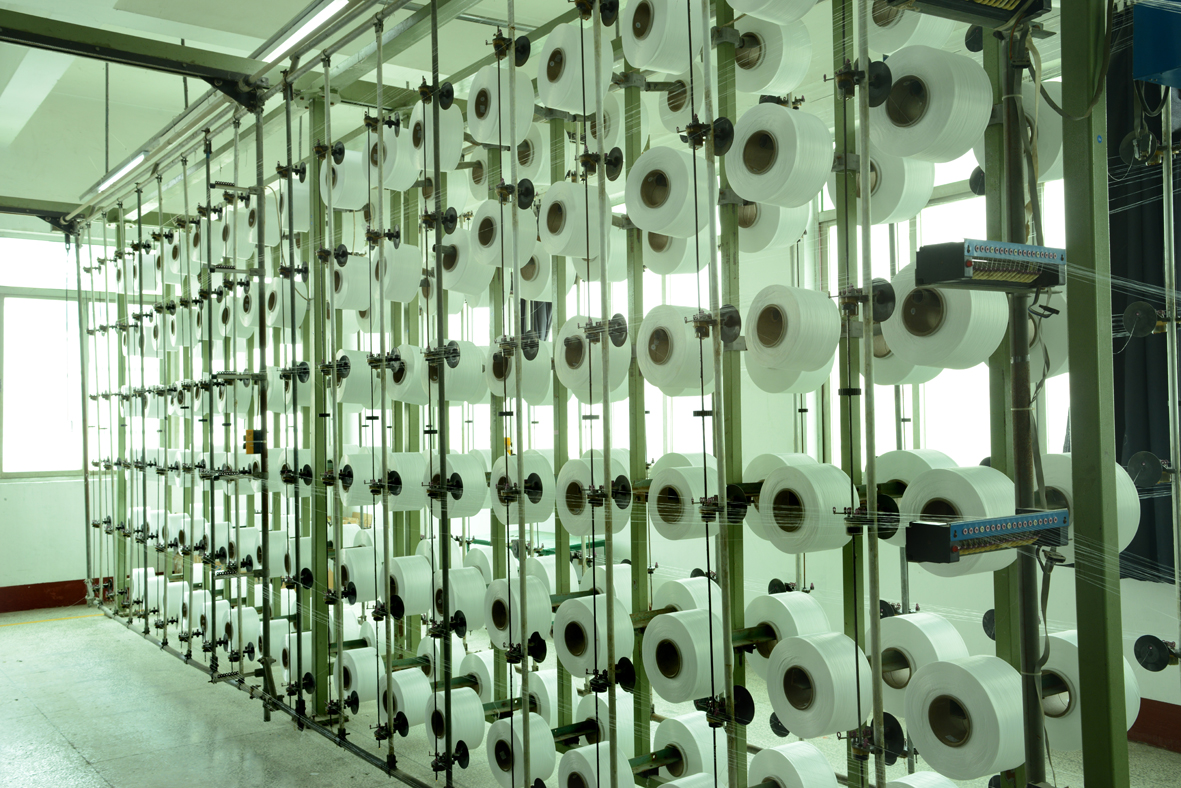

Twisting- yarn workshop 、Wrapping workshop: Every silk and thread is selected out of the best. This is to ensure the high quality by using the best raw materials. Woven jacquard workshop 、 Knitting workshop: With advanced international equipment, standardized production process and strict quality management system, we are committed to establish a higher production standard. Dyeing workshop: Fabrics are richly-dyed and environmentally friendly with guarantee on fastness. Quality inspection workshop: Quality oriented, possession of a complete and strict quality management system, Wester persists in quality as the utmost principle of our company. |